Ni-MH battery chemical composition

The “metal” part of a Ni-MH battery is actually the metal intercalation. Many types of metal intercalation have been used in the manufacture of Ni-MH batteries, and they fall into two main categories. The most common are AB5, where A is a mixture of rare earth elements (or) titanium (Ti), and B is nickel (Ni), cobalt (Co), manganese (Mn), (or) aluminium (Al). The “multi-component” electrodes of some high-capacity batteries are mainly made up of AB2, where A is titanium (Ti) or vanadium (V) and B is zirconium (Zr) or nickel (Ni), plus some chromium (Cr), cobalt (Co), iron (Fe) and/or manganese (Mn). All these compounds play the same role: the reversible formation of metal hydrides. When the battery is charged, hydrogen ions (H+) are released from the potassium hydroxide (KOH) electrolyte, which is absorbed by these compounds to avoid the formation of hydrogen gas (H2) in order to maintain the pressure and volume inside the battery. When the battery is discharged, these hydrogen ions are returned to their original location by the opposite process.

Ni-MH battery weight

In terms of voltage per cell, Ni-MH and Ni-Cd are both 1.2V, while Li-ion batteries are 3.6V, with Li-ion batteries having three times the voltage of the other two. And the weight of the same battery is almost equal for Li-ion and Ni-Cd batteries, while Ni-MH batteries are heavier. It can be seen that the weight of each battery itself is different, but the high voltage of 3.6V of Li-ion battery can reduce the number of individual battery combinations by one-third under the same voltage output and reduce the weight and volume of the formed battery.

Ni-MH battery memory effect

Ni-MH batteries have the same memory effect as Ni-Cd batteries. Therefore, regular discharge management is also necessary. This regular discharge management is handled in a vague manner, and even in some cases with incorrect knowledge (each discharge or discharge after several uses varies from company to company) This tedious discharge management cannot be avoided when using Ni-MH batteries. In contrast, Li-ion batteries are very convenient and simple to use because they have no memory effect at all. It is possible to charge the battery directly without having to worry about the residual voltage, so that the charging time is naturally shortened.

Ni-MH battery capacity

The higher the capacity of different battery types (especially in terms of size), the longer the duration of use. The higher the capacity, the better. But the same battery model with the same nominal capacity (e.g. 600mAh) will have a different initial capacity in practice: for example, if one is 660mAh and the other is 605mAh, then the 660mAh is better than the 605mAh.

The result is that after a few dozen cycles, the high-capacity battery rapidly loses capacity, while the low-capacity battery remains strong. Many domestic cell manufacturers often use this method to obtain high-capacity batteries. After half a year of use, the standby time is a mess.

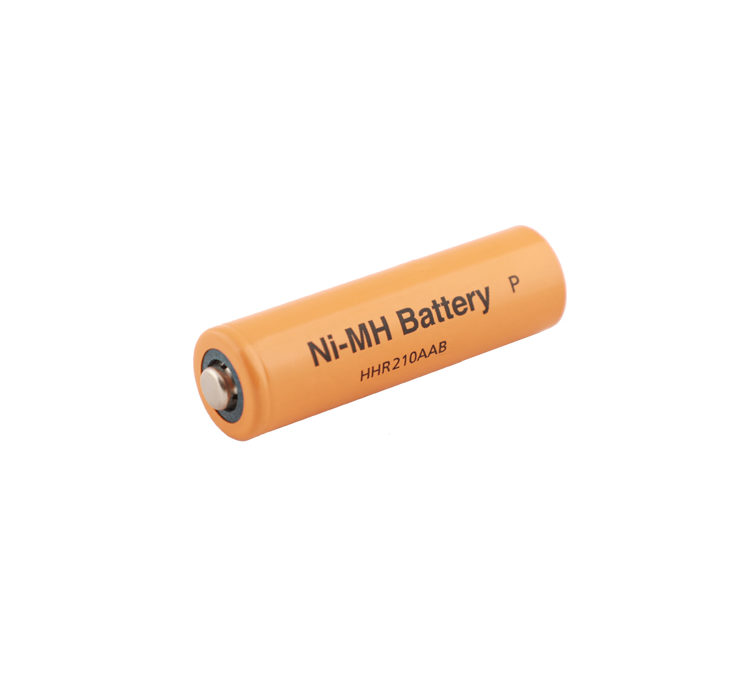

The AANi-MH batteries for civilian use (i.e. No. 5 batteries) are usually 1400mAh, but there are also those with a very high capacity (1600mAh), for the same reason.

The cost of increasing the capacity is the sacrifice of cycle life, and manufacturers cannot really increase the capacity of a battery without making an effort to modify the battery material. Battery material-specific surface area research is very important, battery material-specific surface area test data only using the BET method to detect the results are real and reliable, there are currently many domestic instruments that can only do direct comparison method of detection, now the domestic is also eliminated. At present, the BET method is used at home and abroad, and the standards for the determination of specific surface areas are based on the BET method, please refer to the Chinese National Standard (GB/T19587-2004) – Method for the determination of the specific surface area of solid substances by gas adsorption BET principle. Due to the different adsorption capacities of the samples, some samples can take up to a whole day to test. If the testing process is not fully automated, the tester must be present at all times and must be highly concentrated, observing the instrument panel and manipulating the knobs. The F-Sorb2400 specific surface area tester is a true BET tester (with direct comparison), and more importantly, the F-Sorb2400 is the only fully automated and intelligent specific surface area tester in China to date, with high international consistency and stability of test results, while reducing human error and improving The test results are highly consistent and stable with international standards, while reducing human errors and increasing the accuracy of the test results.