Mar 25, 2022 | Company News

Lithium manganate batteries are a class of lithium-ion batteries. For the classification of lithium-ion batteries, as their negative electrode is basically a carbon material, the main way of classification in the industry is by the lithium-ion battery cathode material and respectively. The so-called lithium manganate battery refers to the cathode using lithium manganate material battery. So, what is lithium manganate? It is produced by mixing and sintering EMD (a raw material that was used for mercury-free alkaline manganese batteries) and lithium carbonate (also a raw material), together with the appropriate additives.

Nowadays, when we talk about lithium manganate, we say that it has a spinel structure, which refers to the crystal shape in which it is used in lithium batteries, and when lithium manganate is not used in lithium batteries, there is also a layered structure. The spinel structure is relatively more stable than the lamellar structure (although the stability of the different shapes in the geometry seems to come to mind based on the chemical properties), and therefore the spinel structure is currently used in practical applications.

In addition to lithium manganate, lithium cobaltate and ternary lithium battery cathodes are also spinel structures, but the spinel structure of lithium manganate has a very distinct character compared to its two counterparts, i.e. both advantages and disadvantages are very prominent. Its advantages are: low temperature resistance, good multiplier performance, relatively easy to prepare, disadvantages are: the material itself is not stable, need to be mixed with other materials, high temperature performance is poor, cycle performance is poor, fast decay. These disadvantages of lithium manganate result from the properties of manganese. However, the widespread availability of manganese gives it a significant cost advantage.

Because lithium manganate is such a distinctive material, its advantages have been exploited and its disadvantages suppressed, so that lithium manganate batteries are used in different applications, usually referred to as Class A and Class B. Class A is used for power batteries, focusing on safety and cycling performance, requiring a reversible capacity of 100 to 115 mAh/g and maintaining 80% capacity after 500 cycles. Class B is mainly used for Consumer electronics (mobile phone category), which are characterised by high capacity, generally requiring a reversible capacity of 120 mAh/g, but cycle performance only requiring 60% capacity to be maintained after 300~500 cycles.

The different performance of these two types of battery is achieved during the production process. As mentioned earlier, the preparation of lithium manganate is relatively simple. If it is to be processed into positive electrodes suitable for A and B batteries respectively, the additions and operational processes will be different and different synthesis methods will be used. Specifically, there are: high temperature solid phase method, melt impregnation method, microwave synthesis method, co-precipitation method, hydrothermal synthesis method, etc. If each preparation method is described in detail, it is a matter of manufacturing process, and here it is sufficient to know that there are multiple methods.

Mar 24, 2022 | Company News

Colloidal batteries

The colloidal lead-acid battery is an improvement on the ordinary lead-acid battery with liquid electrolyte, replacing the sulphuric acid electrolyte with a colloidal electrolyte, which improves safety, storage capacity, discharge performance and service life compared to the ordinary battery.

The gel electrolyte is used in lead-acid batteries, and there is no free liquid inside the battery, so the electrolyte has a large capacity in the same volume, and the heat dissipation capacity is high, which can avoid the thermal runaway phenomenon of general batteries.

Colloidal battery working principle

The performance of the colloidal lead-acid battery is better than that of the valve regulated sealed lead-acid battery. The colloidal lead-acid battery has the advantages of stable performance, high reliability, long service life, adaptability to ambient temperature (high and low temperature), ability to withstand long time discharge, cycle discharge, deep discharge and high current discharge, self-protection from over-charging and over-discharge, etc.

Domestic colloidal lead-acid batteries for electric bicycles are filled with silica gel and sulphuric acid solution between the positive and negative plates of the battery through vacuum filling in the AGM partition. This is because the gel surrounds both the positive and negative plates and the oxygen produced on the positive plate cannot diffuse to the negative plate and cannot be reduced to the active material lead on the negative plate, which can only be discharged by the exhaust valve, in line with the liquid-rich battery.

Differences between colloidal and lead-acid batteries

Colloidal battery performance characteristics

1、Fumed silica formulates high quality colloid, the electrolyte is evenly distributed and there is no acid stratification phenomenon.

2、The electrolyte is fixed in a gel state, no flow, no leakage and uniform reaction of all parts of the pole plate.

3、Adopting tight assembly technology, with excellent high rate discharge performance.

4、Excess electrolyte, large thermal capacity of the battery, strong thermal dissipation ability, wide working temperature range.

5、All adopt high purity raw materials, the battery self-discharge is extremely small.

6、Adopting gas recombination technology, the battery has extremely high sealing reaction efficiency, no acid mist precipitation, safe and environmental protection, no pollution.

7、Adopting special design and highly reliable sealing technology to ensure that the battery is sealed, safe and reliable to use.

Colloidal battery application range

1、Communication system: switchboard, microwave station, mobile base station, data centre, radio and broadcasting station.

2、Power plants and power transmission systems.

3、Solar and wind power generation systems

4、Signal systems and emergency lighting systems

5、EPS and UPS systems

Difference between colloidal and lead-acid batteries

Lead-acid batteries

A battery whose electrodes are mainly made of lead and its oxides and whose electrolyte is a sulphuric acid solution. In the discharged state, the main component of the positive electrode is lead dioxide and the negative electrode is lead; in the charged state, the main component of both positive and negative electrodes is lead sulphate. It is divided into exhaust type battery and maintenance-free lead-acid battery.

Performance characteristics of lead-acid battery.

1、Safe and sealed

In normal operation, the electrolyte will not leak out from the terminals or the shell of the battery.

2、No free acid

A special liquid absorbing partition keeps the acid inside and there is no free acid inside the battery, so the battery can be placed in any position.

3、Drainage system

When the internal pressure of the battery exceeds the normal level, the VRLA (short for “Valve-Regulated LeadAcid Battery”) will release the excess gas and automatically reseal the battery to ensure that there is no excess gas in the battery.

4. Simple maintenance

Thanks to the unique gas compound system, the gas produced is converted into water, so there is no need to add water during the use of the battery.

5. Long service life

With the use of lead-calcium alloy bar plate with corrosion-resistant structure, the battery can be used for 10-15 years on a floating charge.

6、Stable quality and high reliability

Adopting advanced production process and strict quality control system, the quality of the battery is stable and the performance is reliable. Voltage, capacity and sealing are 100% tested on line.

Mar 22, 2022 | Company News

Lithium battery series and parallel connection definition

Due to the limited voltage and capacity of a single battery, it is necessary to combine them in series and parallel to obtain a higher voltage and capacity in order to meet the actual power supply requirements of the equipment.

Lithium batteries in series: voltage is added, capacity remains the same, internal resistance increases.

Lithium batteries in parallel: the voltage remains the same, the capacity is added, the internal resistance is reduced and the power supply time is extended.

Lithium batteries in series and parallel: the batteries are combined in parallel and in series, resulting in higher voltage and higher capacity.

Series voltage: 3.7V single cells can be assembled into a battery pack with a voltage of 3.7*(N)V as required (N: number of single cells)

Such as 7.4V, 12V, 24V, 36V, 48V, 60V, 72V, etc.

Parallel capacity: 2000mAh single cells can be assembled into battery packs with a capacity of 2*(N)Ah as required (N: number of single cells)

Such as 4000mAh, 6000mAh, 8000mAh, 5Ah, 10Ah, 20Ah, 30Ah, 50Ah, 100Ah, etc.

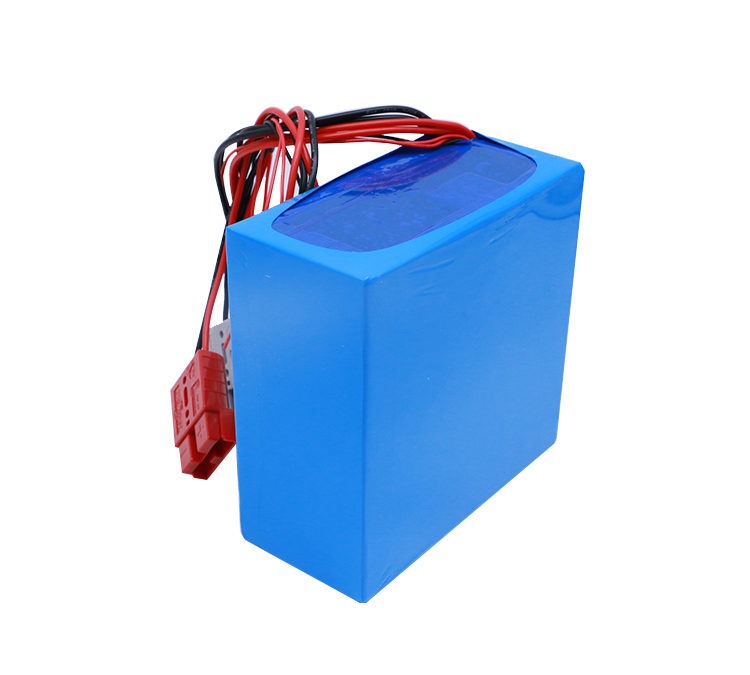

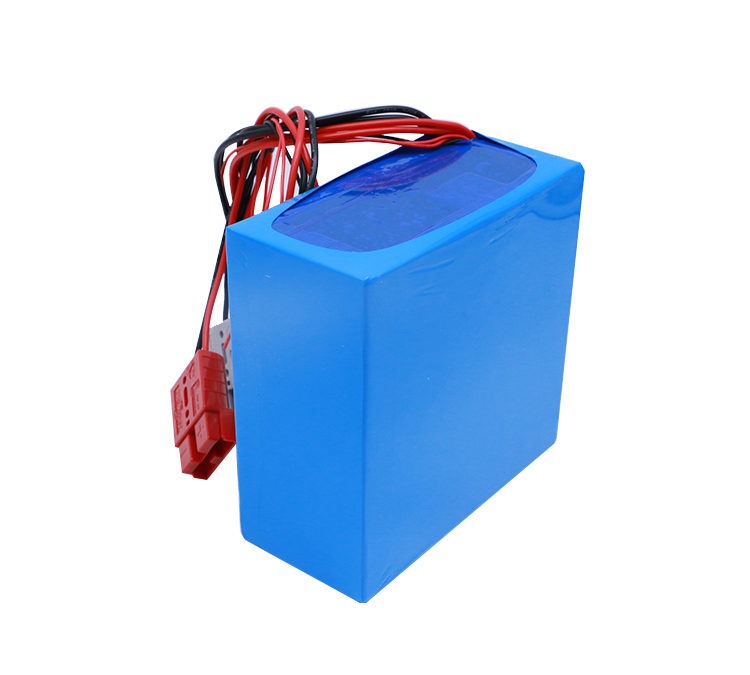

Li-ion Battery PACK

Li-ion battery PACK refers to the processing and assembly of Li-ion battery packs and packaging. The process of assembling lithium cells into a group is called PACK, which can be a single cell or a series-parallel lithium battery pack, etc. Lithium Battery Pack usually consists of plastic shell, protection plate, battery cell, output electrode, connection with touch piece, and other insulating tape, double-sided tape, etc.

Lithium cell: the core part of the finished battery

Protection board: overcharge, overdischarge, overcurrent, short-circuit, NTC temperature control and other intelligent protection functions.

Plastic shell: support skeleton of the whole battery; positioning and fixing of the protection plate; carrying all other non-shell parts and limiting the position.

Terminal leads: can provide a variety of terminal line charging and discharging interface for various electronic products, energy storage products, backup power supply.

Nickel tabs/brackets: connecting and fixing components for electric cells

Lithium battery series and parallel combination

Due to the safety of lithium batteries, an external protection board must be used for the monitoring of each battery, the use of batteries is generally not recommended in parallel, if parallel must ensure the consistency of the parameters of the battery (capacity, internal resistance, etc.), in addition to the series use of the battery must also be consistent parameters, otherwise the performance of the battery pack will be much worse than the performance of a single cell.

The purpose of the lithium battery pairing is to ensure that the capacity, voltage, internal resistance and effect of each battery in the battery pack is consistent, inconsistency will lead to the use of lithium batteries in the process of various parameters farther and farther apart, resulting in voltage imbalance, over time will be over-charged, over-discharged, capacity does not play out, causing the risk of explosion and fire.

Precautions for series and parallel connection of lithium batteries

Do not use different brands of batteries together.

Do not use batteries of different voltages together.

Do not mix different capacities or old and new lithium batteries together.

Do not mix batteries of different chemical materials, e.g. NiMH and Li-ion batteries.

Replace all batteries when they are running low.

Use lithium battery protection plates with corresponding parameters.

Choose batteries with the same performance, generally lithium batteries used in series and parallel need to be paired with lithium battery cells. The standard of pairing: voltage difference ≤ 10mV, internal resistance difference ≤ 5mΩ, capacity difference ≤ 20mA

Mar 21, 2022 | Company News

18650 lithium battery in the 18650 these numbers, representing the appearance of the size: where 18 means the diameter of 18mm, 65 means the length of 65mm, 0 means for the cylindrical battery. It is a standard lithium-ion battery type set by SONY in Japan to save cost, called 18650 lithium battery. 18650 lithium battery pack usually consists of three parts: 18650 cell, protection board (usually called PCBA) and shell structural parts. The best 18650 Li-ion battery pack should choose the best of the following three components.

1. Use high quality 18650 cells

The best 18650 Li-ion battery pack should be composed of first-tier brand cells, with mainstream capacities ranging from 1800mAh to 3500mAh. single cells undergo a series of safety tests and performance tests.

2. Multi-functional protection circuit board (PCBA)

The core component of the Li-ion battery protection board is the protection IC. The main materials that make up the protection board are PCB, magnetic field effect tube (MOS tube), NTC, PTC, capacitor, resistor, diode, triode, etc.

Overcharge protection: When the voltage of a string of the battery pack is greater than the (overvoltage) maximum value and the protection delay is reached, the IC controls the CMOS to shut down the charging circuit.

Over-discharge protection: When the voltage of one string of the battery pack is less than the (under-voltage) maximum value, and the protection delay is reached, the IC controls the DMOS to shut down the discharge point circuit.

Over-current and short-circuit protection: When the battery pack P+ and P- output currents exceed the over-current/short-circuit current value and the over-current/short-circuit delay is reached, the control circuit controls the discharge DMOS to shut down the discharge circuit and stop discharging.

High and low temperature protection: When the temperature sensor reaches the temperature threshold and the protection delay is reached, the control circuit controls the shutdown of the charging and discharging MOS tube to stop charging and discharging.

The Li-ion battery protection board also has functions such as power detection, balance display, battery working status display and communication remote control.

3. Shell structural parts

According to the demand of electric apparatus, design the shell structure to match it, usually with plastic shell, hardware shell, simple PVC heat shrink, etc.

4. Exquisite lithium battery PACK technology

For 18650 lithium battery pack, superb PACK capability is crucial to have advanced equipment, skilled technical workers, mature management mode and strict production requirements in order to ensure that no omission will occur in the important aspects of 18650 lithium battery pack such as welding, testing, aging, pre-shipment testing, etc. and produce the best 18650 lithium battery pack.

Mar 18, 2022 | Company News

The technological progress of cylindrical lithium-ion batteries mainly comes from the innovative research and application progress of key battery materials, further improving battery performance, improving quality, reducing costs, and improving safety through the development of new materials. To meet the requirements of downstream applications for battery-specific energy enhancement, high voltage materials can be used by adopting high specific capacity materials on the one hand, and by increasing the charging voltage on the other.

Cylindrical lithium-ion batteries have developed from 14500 to Tesla 21700 batteries, and in the recent mid-term development, while optimizing the existing system lithium-ion power battery technology to meet the needs of the scale development of new energy vehicles, the focus is on developing new lithium-ion power batteries to improve their safety, consistency and life span and other key technologies, and simultaneously carry out forward-looking research and development of new system power batteries.

For the medium and long-term development of cylindrical lithium-ion batteries, while continuing to optimize and enhance new lithium-ion power batteries, focus on the development of new system power batteries, significantly improve the specific energy, significantly reduce costs, and achieve the radicalization and large-scale application of new system power batteries.

Comparison between lithium cylindrical and lithium square batteries

1. Battery shape: square size can be designed arbitrarily, while the cylindrical battery can not be compared.

2. Multiplier characteristics: cylindrical battery welding multi-pole lug process limitations, multiplier characteristics are slightly worse than the square multi-pole lug battery.

3. Discharge platform: Theoretically speaking, the discharge platform of lithium batteries with the same positive and negative electrode materials and electrolytes should be the same, but the discharge platform of square lithium batteries is slightly higher.

4. Product quality: The manufacturing process of cylindrical batteries is more mature, with a low chance of secondary slitting defects in the pole piece, and the maturity and automation of the winding process are relatively high, while the iteration process is still semi-manual, which has a negative impact on the quality of the battery.

5. Lug welding: cylindrical battery lugs are easier to weld than square lithium batteries; square lithium batteries are prone to false welding, which affects the quality of the battery.

6. PACK formation: cylindrical batteries are easier to use, so PACK technology is simple and heat dissipation is good; square lithium batteries have to solve the problem of heat dissipation when PACK.

7. Structural characteristics: square lithium batteries are less chemically active at the corners, the energy density of the battery is easy to decay with long-term use, and the range is shorter.

Cylindrical lithium battery and soft pack lithium battery comparison

1. Soft pack battery safety performance is better, soft pack battery in the structure of the aluminum-plastic film packaging, the occurrence of safety problems, soft pack battery will generally bulge crack, unlike the steel or aluminum shell battery cell explosion; in the safety, performance is better than the cylindrical lithium battery.

2. Soft pack battery weight is relatively light, soft pack battery weight is 40% lighter than the same capacity of steel-cased lithium batteries, 20% lighter than cylindrical aluminum-cased lithium batteries; internal resistance is small, the internal resistance of soft pack batteries is smaller than lithium batteries, which can greatly reduce the self-consumption of the battery;

3. Soft pack battery cycle performance is good, soft pack battery cycle life is longer, 100 times less than the cylindrical aluminum shell battery cycle decay 4% to 7%;

4. Soft pack battery design is more flexible, the shape can be any shape, can be thinner, can be customized according to customer needs, the development of new cell models. The cylindrical lithium battery does not have this condition.

5. The shortcomings of soft pack batteries compared to cylindrical lithium batteries are poor consistency, higher cost, and easy leakage. The high cost can be solved by large-scale production, and the leakage can be solved by improving the quality of aluminum-plastic film.