Feb 24, 2022 | Company News

(1) In general, new Ni-MH batteries contain only a small amount of power, so you should charge them before using them after purchase. However, if the battery has been shipped from the factory for a short period of time and has sufficient power, it is recommended to use it first and then charge it.

(2) Newly purchased Ni-MH batteries generally need to be charged and used 3-4 times before the performance is at its best. Many friends encounter minor problems with the first charge, such as the number of pictures taken after the first charge is not as much as they thought. After 3-4 times of charging and use, they will all be solved.

(3) Although the memory effect of Ni-MH battery is small, it is still recommended that you try to recharge it after each use, and to fill it up at once, not to use it for a while and then charge it again. This is an important point to “prolong life”.

(4) When charging the battery, pay attention to the heat dissipation around the charger, too deliberately with what fan blowing is not necessary, but we should pay attention to the charger around not to place too many debris. The average user often does not have a special storage bag for the battery; users will habitually put the battery away after replacing it, regardless of whether the place where it is placed is clean and damp. The consequence of this is that the batteries get dirty easily, the contacts are prone to contact with metal? The result is that the battery can get dirty, the contacts can easily come into contact with metal, such as keys, and it can easily get wet, all of which are the enemy of the battery. Advice: Users should set up a special place for the battery and keep it clean. To avoid problems such as power loss, keep the contacts at both ends of the battery and the inside of the battery cover clean, using a soft, clean dry cloth to wipe gently when necessary.

(5) When not in use for a long period of time, remember to remove the battery from the battery compartment and place it in a dry environment recommended into the branded battery compartment, which will prevent the battery from short circuiting.

(6) Ni-MH batteries that have not been used for a long time will naturally enter a “dormant” state after a few months of storage, and the battery life will be greatly reduced. If the Ni-MH battery has been stored for a long time, it is advisable to charge it with a slow charger first. This is because: according to tests, the best conditions for storing Ni-MH batteries are around 80% charged. This is because Ni-MH batteries have a large self-discharge (around 10%-15% a month). If the battery is completely discharged and then stored and not used for a long time, the self-discharge phenomenon of the battery will cause the battery to over-discharge and will damage it. Don’t believe me? Then think about whether all newly bought NiMH rechargeable batteries are still charged, of which this is the truth. Advice: compare, correct and start in the right direction to maintain your batteries, otherwise you will not get what you want.

(7) Discharge NiMH. Expert advice. Try not to discharge the Ni-MH battery, over-discharging will lead to charging failure, and the harm of doing so is far greater than the memory effect of the Ni-MH battery itself.

(8) Multimeter self-testing whether the battery is full or not. Generally, before charging Ni-MH battery, the voltage is below 1.2V, and the normal voltage is around 1.4V when it is full. We use this judgment, it is also easy to judge the state of the battery.

(9) Chargers are mainly divided into fast charging and slow charging. The slow charging current is small, usually around 200mA, for example, our common charging current is around 160mA. The charging time is long, it takes about 16 hours to charge an 1800mAh Ni-MH battery. Although the time is slower, the charge will be sufficient and will not damage the battery. The fast charging flow is usually above 400mA and the charging time is significantly reduced to 3-4 hours, which has won everyone’s favour. There are many different types of fast chargers with different prices. So people often wonder why there is such a big difference in price for the same fast charger. A good charger, especially a good fast charger, comes with anti-overcharging protection, for example, our common Panasonic Extreme charger BQ390 is particularly good in this regard, excellent chip software design capabilities in charging the battery, but also to minimize the damage of fast charging to the battery.

(10) The paradox arises that slow charging does not hurt the battery but takes too long to charge; fast charging saves time but hurts the battery, and even the best Panasonic Extreme Charger BQ390 in the world today can only reduce the degree of damage very well, but cannot be completely avoided. The solution to the paradox is to get a fast charger and a slow charger. After a period of charging with the fast charger, let’s say 5 to 10 times, switch to the slow charger for one or two charges. This restores the performance of the battery to its optimum state again.

(11) Batteries are generally used in packs, that is, 4 or 6 in series, when it is important to keep each battery in balance, otherwise the whole pack will be affected by a problem with one of the batteries. Firstly, it is important to ensure that the batteries are of the same capacity, and it is best to choose batteries of the same brand and the same model purchased at the same time. Then, it is important to maintain the same level of charge inside the battery, which simply means that the battery pack is either all full or all empty. If you have a large number of batteries in a group, try to “select” them. In other words, you can connect batteries of similar capacity, voltage and other parameters in series to form a battery pack.

(12) Finally, talk about charging and discharging. The high-grade NI-MH charger is used -DELTAV detects the battery voltage to determine whether the battery is full. The voltage curve when charging the battery is somewhat similar to that when discharging, starting with a relatively fast rise, then slowly rising, and when it is time to charge it, the voltage starts to fall again rapidly, only the fall is not very large. The previously used Ni-Cd batteries are similar, except that the rate and magnitude of the drop is greater than that of the NI-MH. The most common chargers on the market (the cheaper kind) often use constant voltage charging, for example, the old GP rechargeable is 1.4V constant voltage, that is, the battery is charged to 1.4V when there is no more voltage difference, the charging is over. The result of this is that the battery is often not fully charged, especially with some older batteries, and the voltage really added to the battery is even lower due to the increased internal resistance. Moreover, the current of such chargers is often low and charging often takes more than 10 hours. Chargers with -DELTAV automatic cut-off, on the other hand, can be used more reliably for high-current charging, as the charging time can be accurately controlled. High current charging is not as damaging to Ni-MH batteries as one might think. First of all, it is a matter of time, which goes without saying. The higher the current you charge, the higher the current it can discharge. Nowadays, DCs are all electric tigers and the current is not small, so it is a wise choice to charge at a relatively high current, so that the battery can be discharged more cleanly. I generally use 0.5C for charging (my charger has adjustable current). For discharging, in general, it is fine to take the DC to charge after it has gone black, the NI-MH memory effect is very small. However, after a period of use, and to balance the battery, to activate the battery, to control the battery discharge termination voltage, NI-MH battery termination voltage is 0.9V, when discharging, pay attention not to over discharge, to each battery 0.9V when you can stop discharging, NI-MH battery is not as strong as NiCd battery, to overcharge and over discharge and high temperature are more sensitive. Charge and discharge temperature. As a general rule, do not let the temperature of the battery go above 45 degrees. When the battery is full, the battery will be hot, the temperature should be about 42 degrees when filled with high current, do not exceed 45 degrees, otherwise the life will be reduced quickly and the internal resistance of the battery will increase. Also, the battery temperature is high after charging, wait for it to cool down before charging it, and wait for it to cool down before charging. If you do not use the battery again after a long period of time, it is best to recharge and reactivate the battery several times. Usually when using it, pay attention to keep the packaging skin intact, there should be no breakage to avoid short circuit. Do not drop and shock the battery, do not burn it, etc.

Feb 23, 2022 | Company News

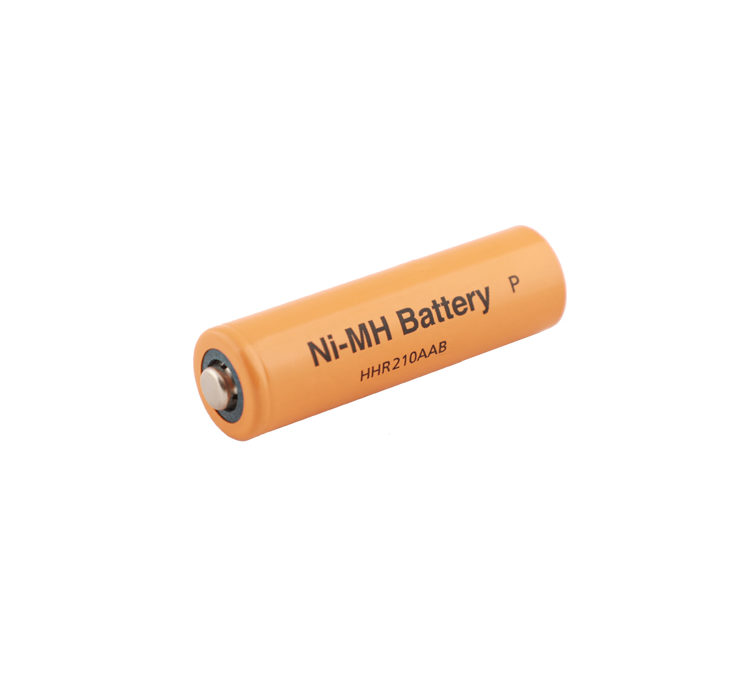

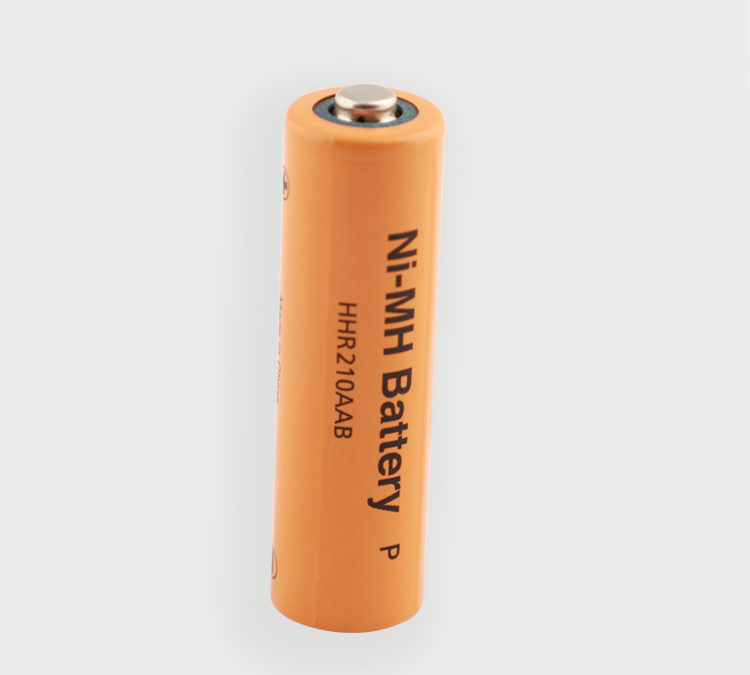

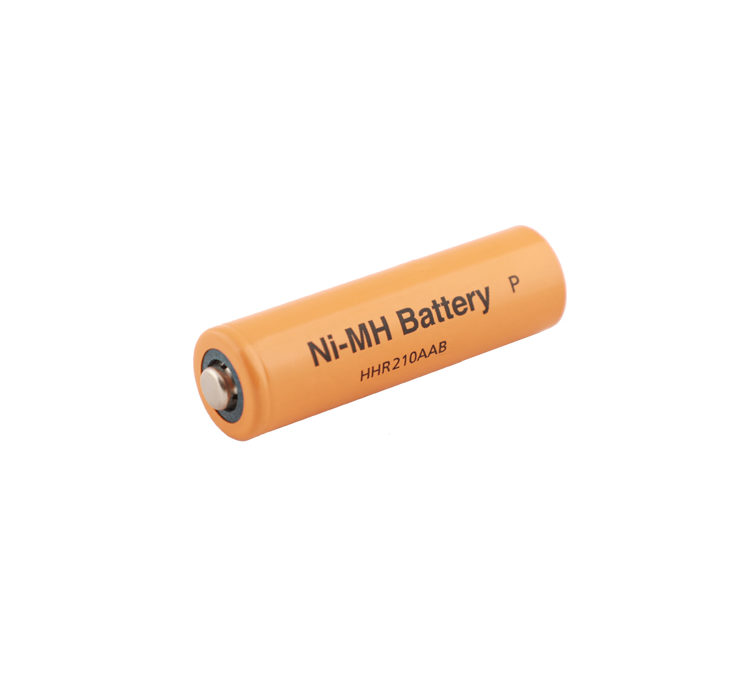

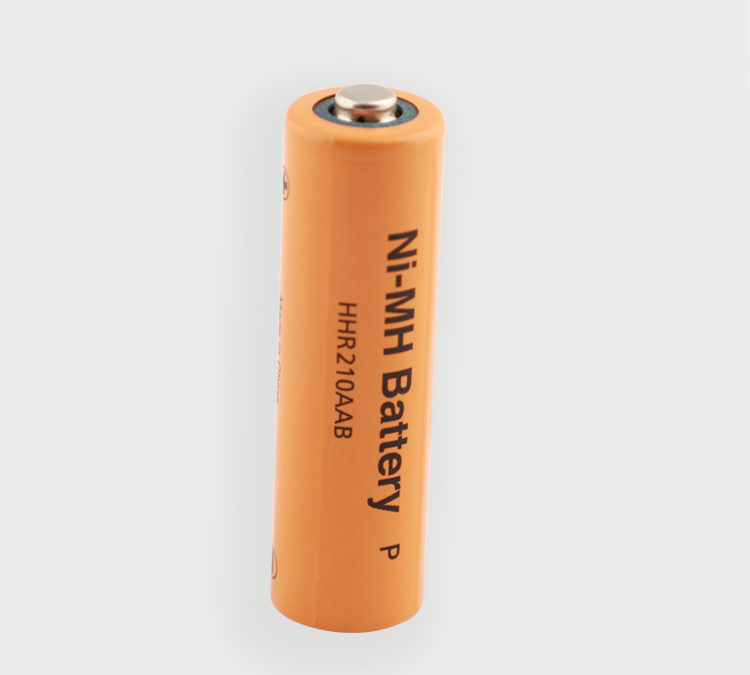

The Ni-MH battery is a composite of hydrogen ions and metallic nickel, which has 30% more power reserve than Ni-Cd batteries, is lighter than Ni-Cd batteries, has a longer service life and is non-polluting to the environment. the disadvantage of the Ni-MH battery is that it is much more expensive than Ni-Cd batteries and has a worse performance than Li-ion batteries.

Ni-MH battery charging

When charging quickly, the microcomputer in the charger can be used to avoid overcharging the battery. Today’s Ni-MH batteries contain a catalyst, which can remove the risk of overcharging in time. 2H2+O2 – catalyst -> 2H2O, but this reaction is only valid for C/10 hours from the start of the overcharge (C=capacity of the battery). When the charging procedure starts, the temperature of the battery rises significantly and some rush chargers (less than 1 hour) include a fan to avoid overheating the battery.

Some manufacturers believe that it is safe to charge Ni-MH batteries with or without a timer using simple constant current (and low current) chargers that allow a long charge current of C/10h (the nominal charge of the battery divided by 10 hours). In fact, some inexpensive cordless phone base stations and the cheapest battery chargers work exactly this way. Although this may be safe, it can have a negative effect on the life of the battery. According to Panasonic’s Ni-MH battery charging guide (link at the bottom of the page), long-term trickle charging (charging at a very low current for a long time) may lead to battery damage; to prevent damage to the battery, trickle charging should be limited to between 0.033 x C per hour and 0.05 x C per hour, with a maximum charge time of 20 hours.

For long-term maintenance of Ni-MH batteries, a low-frequency pulse-high-current charging method is better than a trickle-charging method to maintain good battery condition.

Newly purchased Ni-MH batteries, or those that have not been used for a long time, need a period of “activation” to recharge the battery. Therefore, some new Ni-MH batteries require several charge-discharge cycles before they reach their nominal charge level.

Discharging Ni-MH batteries

Care must also be taken during the use of the batteries. With several batteries connected in series (e.g. the usual arrangement of 4 AA batteries in a digital camera), it is important to avoid completely draining the batteries and thus “Reversecharging”. This can cause irreversible damage to the battery. However, often these devices (such as the digital cameras mentioned earlier) can detect the discharge voltage of a series battery and automatically switch off when it drops to a certain level in order to protect the battery. A single battery is not in danger of this, but will just keep discharging until the voltage reaches 0. This is not damaging to the battery, in fact it is beneficial to maintain the capacity and quality of the battery by discharging it periodically and then recharging it.

Ni-MH batteries have a high self-discharge effect of around 30% or more per month. This is higher than the 20% per month self-discharge rate of Ni-Cd batteries. The higher the battery is charged, the higher the self-discharge rate; when the charge drops to a certain level, the self-discharge rate drops slightly again. The temperature at which the battery is stored has a very significant effect on the self-discharge rate. For this reason, Ni-MH batteries that have not been used for a long time should preferably be charged to 40% “half full”.

Low self-discharge Ni-MH batteries were introduced to the market in 2005 and the manufacturer claims that they can be stored at room temperature at 20°C for a year and still retain between 70% and 85% of their charge, and that they can be recharged with a normal Ni-MH battery charger. Some low self-discharge Ni-MH batteries have better discharge characteristics at low temperatures than alkaline and lithium-ion batteries.

Feb 22, 2022 | Company News

Ni-MH battery chemical composition

The “metal” part of a Ni-MH battery is actually the metal intercalation. Many types of metal intercalation have been used in the manufacture of Ni-MH batteries, and they fall into two main categories. The most common are AB5, where A is a mixture of rare earth elements (or) titanium (Ti), and B is nickel (Ni), cobalt (Co), manganese (Mn), (or) aluminium (Al). The “multi-component” electrodes of some high-capacity batteries are mainly made up of AB2, where A is titanium (Ti) or vanadium (V) and B is zirconium (Zr) or nickel (Ni), plus some chromium (Cr), cobalt (Co), iron (Fe) and/or manganese (Mn). All these compounds play the same role: the reversible formation of metal hydrides. When the battery is charged, hydrogen ions (H+) are released from the potassium hydroxide (KOH) electrolyte, which is absorbed by these compounds to avoid the formation of hydrogen gas (H2) in order to maintain the pressure and volume inside the battery. When the battery is discharged, these hydrogen ions are returned to their original location by the opposite process.

Ni-MH battery weight

In terms of voltage per cell, Ni-MH and Ni-Cd are both 1.2V, while Li-ion batteries are 3.6V, with Li-ion batteries having three times the voltage of the other two. And the weight of the same battery is almost equal for Li-ion and Ni-Cd batteries, while Ni-MH batteries are heavier. It can be seen that the weight of each battery itself is different, but the high voltage of 3.6V of Li-ion battery can reduce the number of individual battery combinations by one-third under the same voltage output and reduce the weight and volume of the formed battery.

Ni-MH battery memory effect

Ni-MH batteries have the same memory effect as Ni-Cd batteries. Therefore, regular discharge management is also necessary. This regular discharge management is handled in a vague manner, and even in some cases with incorrect knowledge (each discharge or discharge after several uses varies from company to company) This tedious discharge management cannot be avoided when using Ni-MH batteries. In contrast, Li-ion batteries are very convenient and simple to use because they have no memory effect at all. It is possible to charge the battery directly without having to worry about the residual voltage, so that the charging time is naturally shortened.

Ni-MH battery capacity

The higher the capacity of different battery types (especially in terms of size), the longer the duration of use. The higher the capacity, the better. But the same battery model with the same nominal capacity (e.g. 600mAh) will have a different initial capacity in practice: for example, if one is 660mAh and the other is 605mAh, then the 660mAh is better than the 605mAh.

The result is that after a few dozen cycles, the high-capacity battery rapidly loses capacity, while the low-capacity battery remains strong. Many domestic cell manufacturers often use this method to obtain high-capacity batteries. After half a year of use, the standby time is a mess.

The AANi-MH batteries for civilian use (i.e. No. 5 batteries) are usually 1400mAh, but there are also those with a very high capacity (1600mAh), for the same reason.

The cost of increasing the capacity is the sacrifice of cycle life, and manufacturers cannot really increase the capacity of a battery without making an effort to modify the battery material. Battery material-specific surface area research is very important, battery material-specific surface area test data only using the BET method to detect the results are real and reliable, there are currently many domestic instruments that can only do direct comparison method of detection, now the domestic is also eliminated. At present, the BET method is used at home and abroad, and the standards for the determination of specific surface areas are based on the BET method, please refer to the Chinese National Standard (GB/T19587-2004) – Method for the determination of the specific surface area of solid substances by gas adsorption BET principle. Due to the different adsorption capacities of the samples, some samples can take up to a whole day to test. If the testing process is not fully automated, the tester must be present at all times and must be highly concentrated, observing the instrument panel and manipulating the knobs. The F-Sorb2400 specific surface area tester is a true BET tester (with direct comparison), and more importantly, the F-Sorb2400 is the only fully automated and intelligent specific surface area tester in China to date, with high international consistency and stability of test results, while reducing human error and improving The test results are highly consistent and stable with international standards, while reducing human errors and increasing the accuracy of the test results.

Feb 16, 2022 | Company News

Many partners want to know the correct use of lithium batteries, the guys do not rush ha, the next four ways to introduce the correct use of lithium batteries.

Although lithium-ion batteries rarely have the memory effect of nickel-cadmium batteries, the principle of the memory effect is crystallization, in lithium batteries will almost not produce this reaction. However, lithium-ion battery capacity will still decline after multiple charges and discharges, the reasons for this are complex and varied. The main reason is the change in the positive and negative electrode materials themselves. On a molecular level, the cavity structure holding the lithium ions on the positive and negative electrodes gradually collapses and clogs; from a chemical point of view, it is the passivation of the positive and negative electrode materials’ activity and the occurrence of side reactions to generate stable other compounds. Physically, there will also be gradual flaking of the cathode material, etc. In short, this ultimately reduces the number of lithium ions in the battery that are free to move during the charging and discharging process.

1, lithium battery instant charging

This is due to the lithium battery after discharge, will enter the sulphation process, if the immediate charging, you can eliminate the not serious sulphation. Therefore, lithium batteries should be charged as soon as possible after use, to maximize the battery power in a rounded and full state.

2, lithium batteries regularly deep discharge battery

Regularly carrying out a deep discharge is also conducive to “activation” of the battery, which can slightly enhance the capacity of the battery. The general method is to carry out a complete discharge of the battery on a regular basis.

3, storage of lithium batteries

When the battery is not used for a long time, the battery should be disconnected from the vehicle and spaced out for a period of time to replenish the battery to avoid self-discharge, or the power consumption of the protection plate will over-discharge the battery.

4, lithium batteries try to use the original battery charger

Generally do not replace the battery charger at will when it is not mastered. It is recommended to use the original battery charger

Over-charging and over-discharging will cause permanent damage to the positive and negative electrodes of lithium-ion batteries, from the molecular level, it can be intuitively understood that over-discharging will lead to excessive release of lithium ions from the negative carbon and make its lamellar structure collapse, over-charging will put too many lithium ions hard into the negative carbon structure, and make some of the lithium ions can no longer be released. This is why lithium-ion batteries are often equipped with charge and discharge control circuits.

Unsuitable temperatures will trigger other chemical reactions within the lithium-ion battery to create unwanted compounds, so many lithium-ion batteries have protective temperature-controlled diaphragms or electrolyte additives between the positive and negative electrodes. When the battery warms up to a certain point, the compound membrane pore closes or the electrolyte denatures, the internal resistance of the battery increases until it breaks and the battery no longer warms up, ensuring a normal battery charging temperature.

After using most of the year, it is best to go to the maintenance center to do battery maintenance, properly replenish the battery electrolyte, adjust the specific gravity of the electrolyte, check its storage power, keep the specific gravity of the battery electrolyte, if necessary, you can increase the number of times of charging. At the same time, it is important to clean the battery terminals and apply special grease to protect them, as this will ensure that the electric vehicle operates reliably and increase the life of the battery.

Feb 15, 2022 | Company News

Define Of Lead-Acid Battery

The lead-acid battery (VRLA) is a battery whose electrodes are mainly made of lead and its oxides and whose electrolyte is a sulphuric acid solution. In the discharged state, the main component of the positive electrode is lead dioxide and the negative electrode is lead; in the charged state, the main component of both the positive and negative electrodes is lead sulfate.

The nominal voltage of a single-cell lead-acid battery is 2.0V, which can be discharged to 1.5V and charged to 2.4V; in applications, six single-cell lead-acid batteries are often connected in series to form a nominal 12V lead-acid battery, as well as 24V, 36V, 48V, etc.

The Development History Of Lead-Acid Battery

The lead-acid battery was introduced in 1918, initially at 6 V. As the displacement of the internal combustion engine increased and the compression ratio increased, the power provided by the 6 V system was no longer sufficient to meet demand and a 12 V system was introduced in 1950. As the number of electrical devices in cars continued to increase, the 12V system also struggled to meet the power requirements of all the devices and could only cut off high power loads at certain stages, leading to problems such as air conditioning not being available when parked. After the introduction of the start-stop system, the 12V system has reached the limit of its own power output, at which point the continued addition of high-powered appliances such as light-hybrid BSG motors to the 12V system will result in transient currents of up to 1000 amps. This is why in 2011 the German car companies Audi, BMW, Daimler, and VW joined forces to introduce a 48V system to meet the demands of high power vehicle loads. The reason for choosing 48V is that the safe voltage for cars is 60V and the 48V battery charging voltage is up to 56V. 48V is the highest voltage level that can be achieved at a safe voltage.

The 12V low voltage system can be powered by either lead-acid batteries or lithium iron phosphate batteries. Through cost, performance, safety, and supply chain maturity of many comparisons, lead-acid batteries are currently stronger than lithium batteries in all aspects, the only drawback is that the same power, lead-acid batteries are heavier and larger, as the lead-acid batteries for cars are not high power, the increase in weight and occupy a limited cabin volume. Only in the pursuit of extreme lightness will lithium batteries be used instead of lead-acid batteries in the pursuit of extreme weight reduction.

The Working Theory Of Lead-Acid Battery

The composition and working principle of lead-acid batteries consist of positive plates, negative plates, partition plates, electrolytes, plastic tanks, etc. The active substance of the positive electrode of the lead-acid battery is lead dioxide (PbO2), the active substance of the negative electrode is lead (Pb), the electrolyte is dilute sulphuric acid, and the positive and negative electrodes are separated by a partition plate. After discharging the lead-acid battery, the active material PbO2 in the positive electrode is transformed into lead sulfate (PbSO4) and attached to the positive electrode, while the active material Pb in the negative electrode is also transformed into lead sulfate (PbSO4) and attached to the negative electrode, and the sulphuric acid in the electrolyte diffuses into the electrode plate, reducing the concentration of the electrolyte. When the lead-acid battery is charged, the opposite reaction takes place. Through charging and discharging reactions, the lead-acid battery can be used repeatedly until the stored capacity fails to meet the requirements of the appliance when its life is terminated.

Types Of Lead-Acid Battery

1. Ordinary Battery

The ordinary battery’s pole plate is composed of lead and lead oxide, and the electrolyte is an aqueous solution of sulphuric acid. Its main advantage is that the voltage is stable and the price is cheap; the disadvantage is that the specific energy is low (i.e. the electrical energy stored per kilogram of battery) and the service life is short and the routine maintenance is frequent.

2. Dry Charge Battery

Its full name is dry charge lead-acid battery, its main feature is the negative plate has a high storage capacity, in a completely dry state, can save the power obtained within two years, when using, only need to add electrolyte, and so on over 20-30 minutes can be used.

3. Maintenance-Free Battery

Maintenance-free battery due to its own structural advantages, electrolyte consumption is very small, in the service life of the basic do not need to replenish distilled water. It also has the characteristics of shock resistance, high-temperature resistance, small size, and small self-discharge. It is generally twice as long as a normal battery. There are two types of maintenance-free batteries on the market: the first is a one-off electrolyte added at the time of purchase, which does not require maintenance in the future (replenishment); the other is a battery that has been sealed with electrolyte when it leaves the factory so that the user cannot add replenishment at all.

Application Of Lead-Acid Battery

1. Used in a variety of cars, tractors, diesel engines starting and ignition, lighting; starting requires high current discharge, requires the ability to start at low temperature, the small internal resistance of the battery.

2. Used in power plants, substations, communications, hospitals, etc. as a backup power source for protection, automatic control, accident lighting, communications, etc.; the electrolyte is dilute, long life, and simple charging;

2. Used in various battery cars, forklifts, shovels, mining motor cars, etc. As electric traction and lighting power supply; requires thick pole plate, large capacity, 3h~5h rate charge/discharge cycle;

In the end, Lead-acid battery changes our life to a great extent.